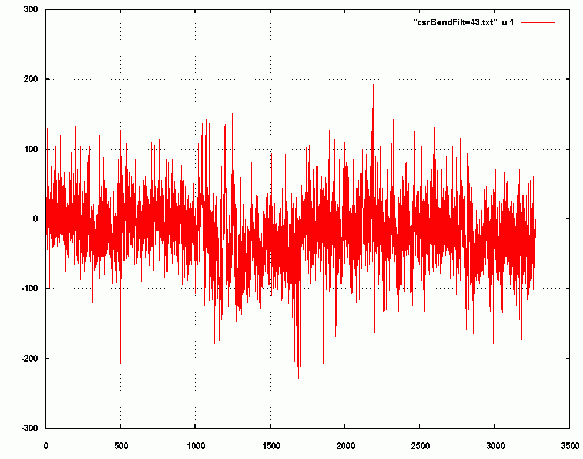

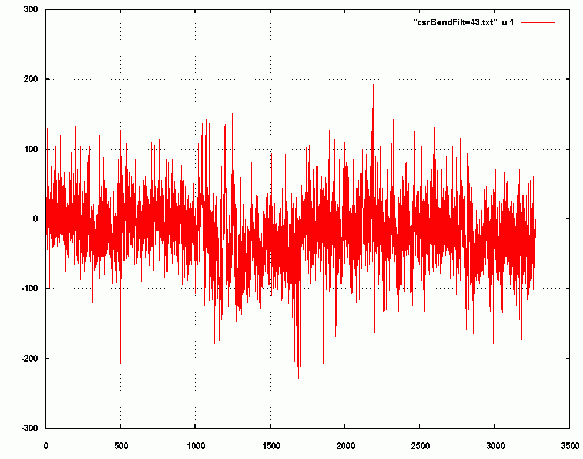

(Click figure to enlarge) Test file of unscaled history is available : csrBendFilt=43.txt with #Highs: 286.00000 #Lows : -238.00000 #Total lines= 3272 For scale factors see result table below.

Crack Initiation: Strain controlled ASTM E606 axial specimen test results for this SAE950X steel

were cut from the plate. Test results courtesy of Phil Dindinger at Rexnord

can be found at https://fde.uwaterloo.ca/Fde/Materials/Steel/Hsla/dindingerSAE950X_1995.html Crack Propagation: CT specimen taken from the plates was tested at R=0.1 Graph of da/dN data Text file of da/dn data

A total of 4 specimens were tested in axial tension and compression with the history shown below.

(Click figure to enlarge) Test file of unscaled history is available : csrBendFilt=43.txt with #Highs: 286.00000 #Lows : -238.00000 #Total lines= 3272 For scale factors see result table below.

-----------Predictions------------

#LifeBlocks TestLoad A B1 B2 C D

# lbs kN -----------Ratio------------------

258.2 34813 155.7 0.3 14 1.9 3.4 0.83

277. 34804 155.7 0.3 14 1.9 3.4 0.83

1212. 24972 111.2 0.4 12.7 1.3 2. 0.85

2163. 20912 93.4 0.5 14 1.2 1.8 1.05