-----Original Message-----[some format changes by moderator]

From: Chernenkoff, Russell

Sent: Thursday, September 02, 2004 8:26 AM

Subject: SAE FD+E Weld Challenge 3 for Oct. 2004 Meeting

Importance: High

--To: SAE FD+E members interested in life prediction of welded structures

Weld Challenge 3

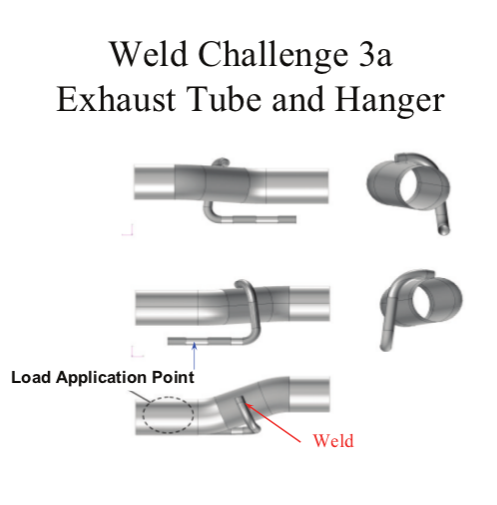

Prediction Challenge 3A:

Paul Lubinski has kindly provided us with our latest

challenge, this one involving an exhaust tube welded to

a hanger. Please see the fatigue.org website for details:

http://www.fatigue.org/Weld/Challenge-3/FDE_weld_info_hanger.ppt

or a Back-up Copy

This document contains everything you should need: drawings and picture

of the test piece, material, constraint conditions, load application

geometry, and the four different fully reversed load levels tested.

The tests were conducted at room temperature, and the exaust tube

and weld filler is 409 stainless while the wire is cold rolled

SAE 1008/1010. All this, and more, are already in the file.

The challenge is, again, to both predict the fatigue life and failure

location on the test piece.

Material

The pipe material is a 409 Stainless steel. The hanger rod material

is SAE1008/1010 cold rolled steel.

Crack Initiation:

Strain controlled ASTM E606 axial specimen test results for 409 stainles

can be found at

https://fde.uwaterloo.ca/Fde/Materials/SSteel/AISI_409_stainless/aisi409.html

Information for materials similar to cold rolled SAE1008/1010 can be

found at

https://fde.uwaterloo.ca/Fde/Materials/Steel/Lowcarbon/lowcarbon.html

Geometry

Details available here:

http://www.fatigue.org/Weld/Challenge-3/FDE_weld_info_hanger.ppt

or a Back-up Copy

Load History

A total of 16 specimens were tested to totally reversed (R=-1)

constant amplitude load control input

at load levels:

4 specimens at +- 1023 N amplitude

4 specimens at +- 845 N amplitude

4 specimens at +- 689 N amplitude

4 specimens at +- 578 N amplitude

Test Results

# Experimental test results

# R= -1.0

Load Ampl.(N) Experiment Cycles to Failure

------------- --------------------------

1023 72,000 +/-52,000

845 390,000 +/-240,000

689 1,110,000 +/-120,000

578 3,000,000 +/-1,000,000

Back to Case Studies

Back to Home page