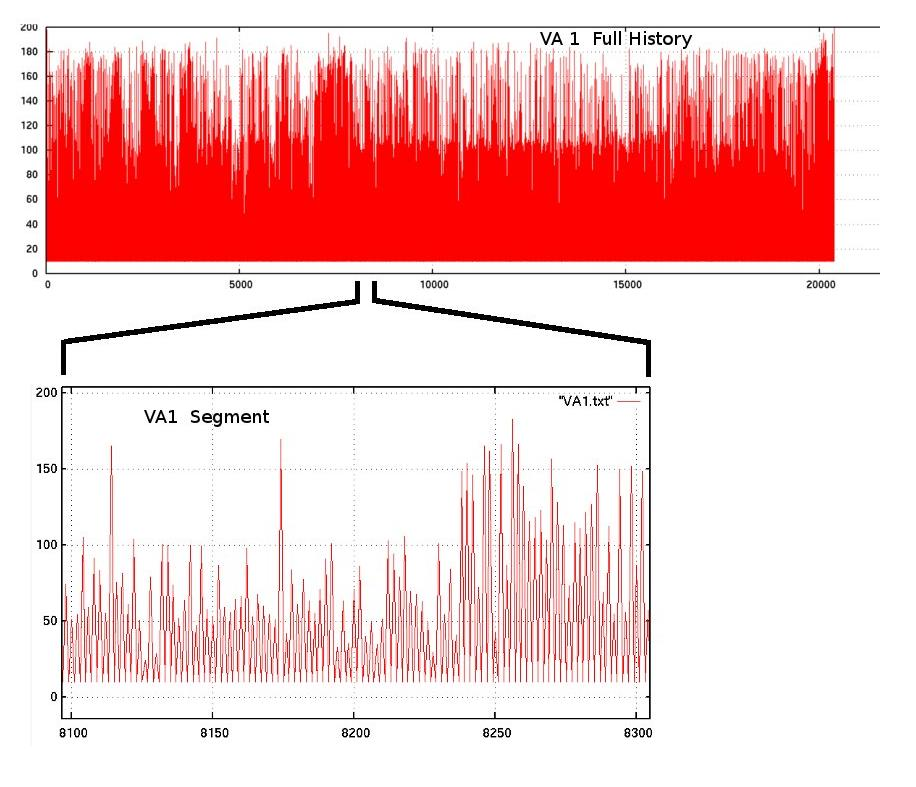

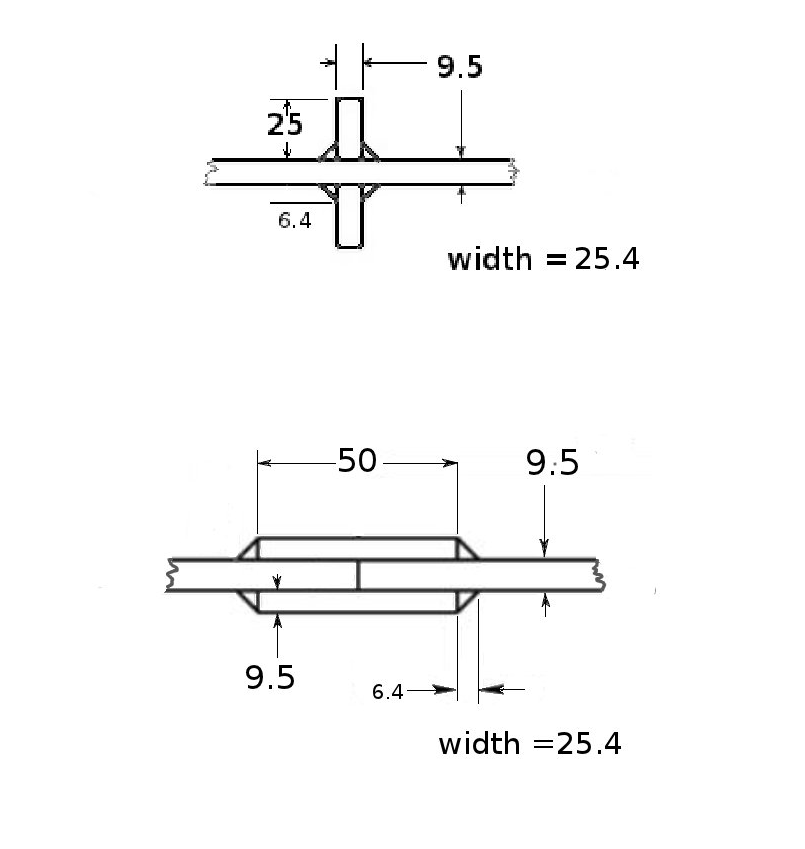

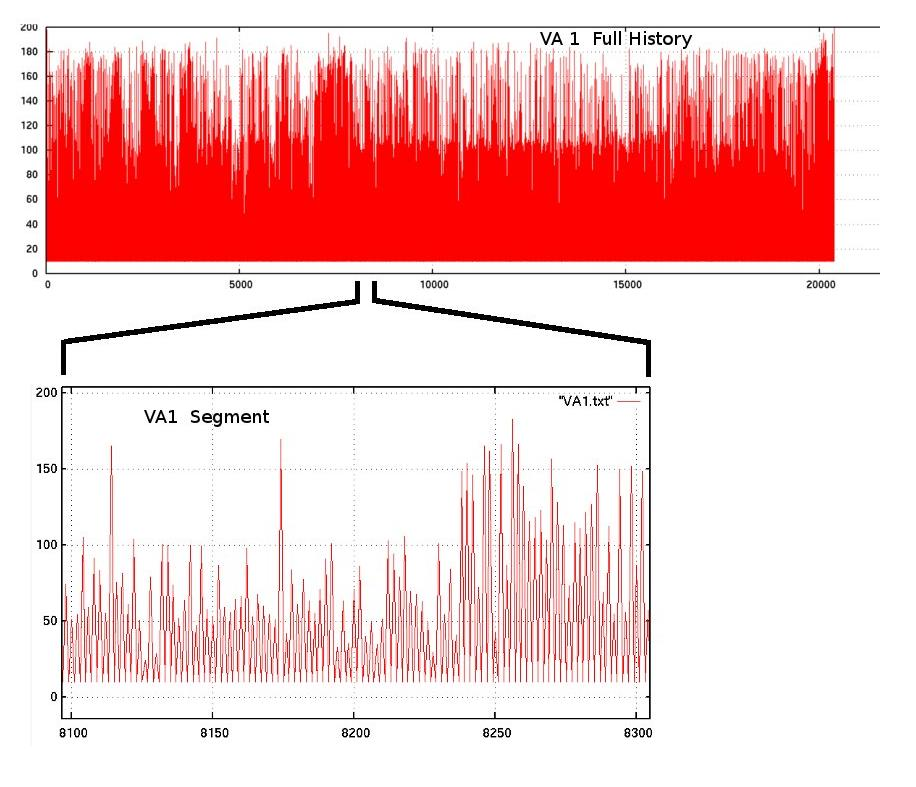

Fig. 3: Variable amplitude history VA1; max=200, min=10.07

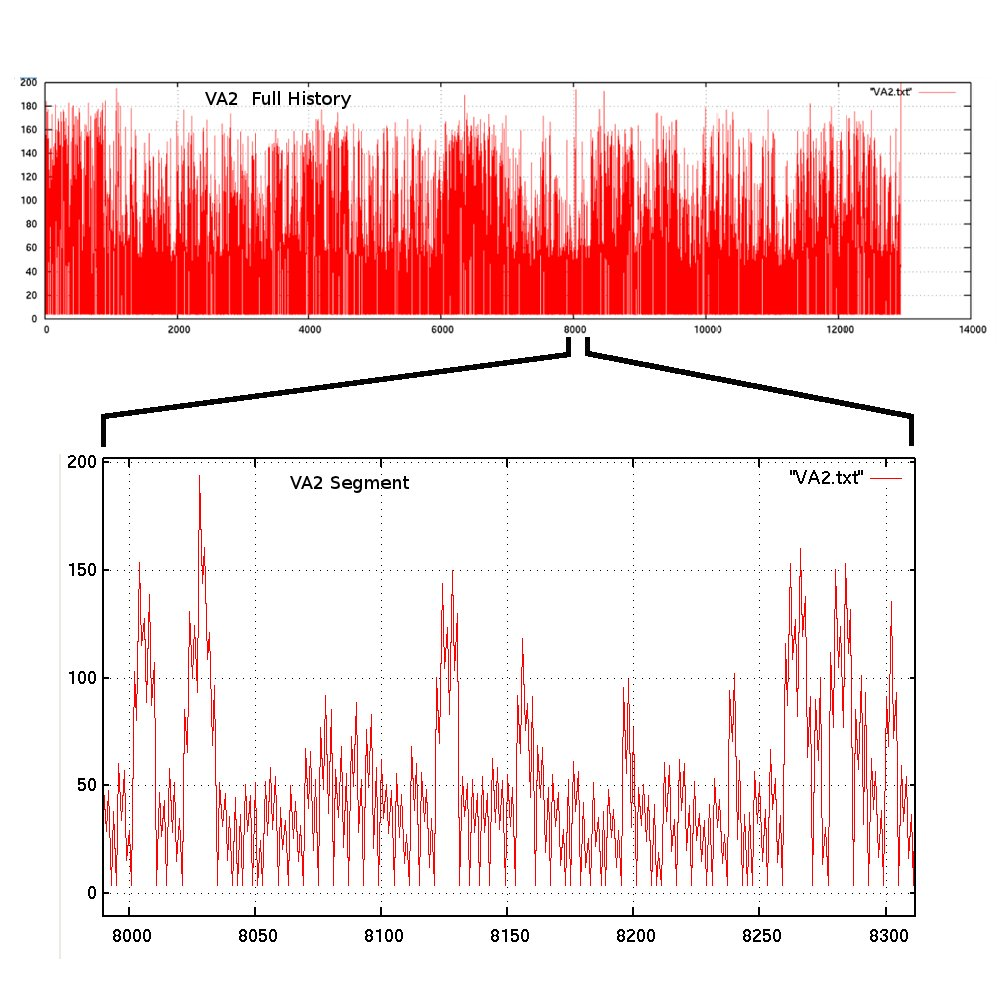

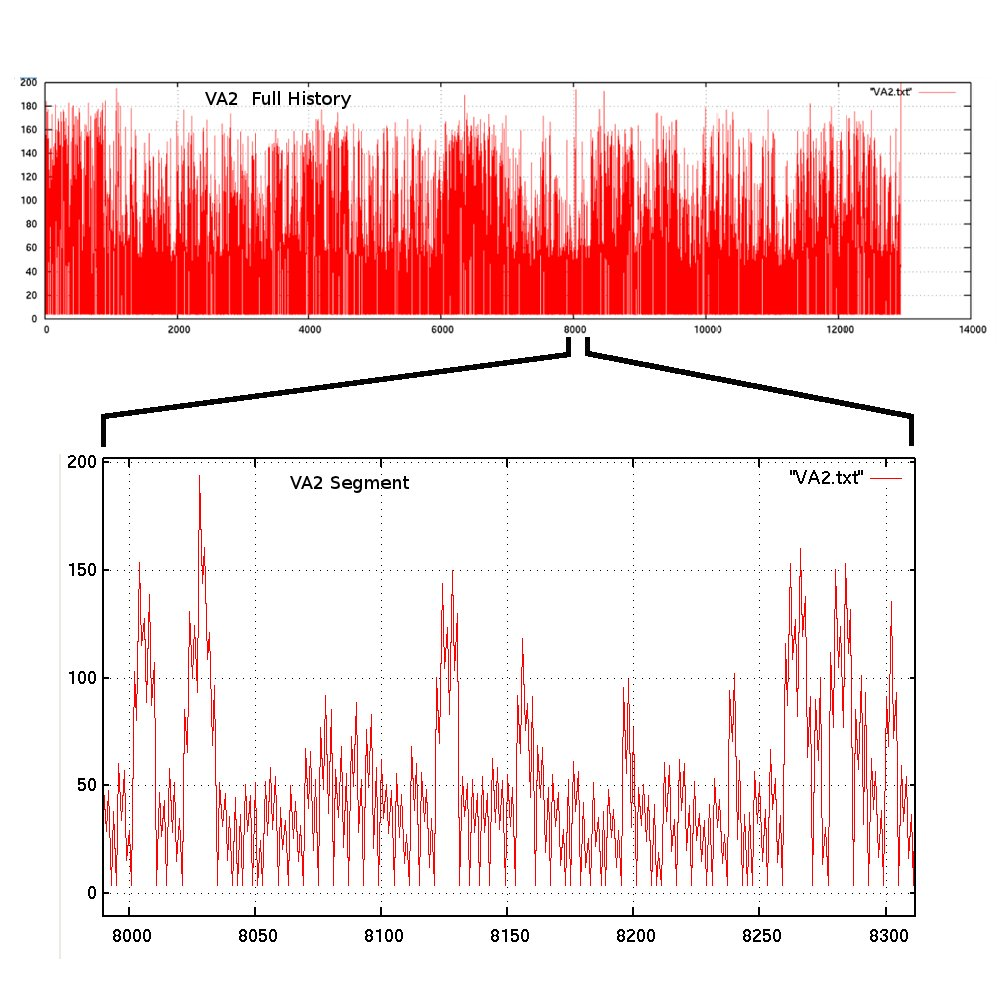

Fig. 4: Variable amplitude history VA2; max=200, min=3.94

Digital Versions of Test Histories:

"... transverse stiffeners and laps, were welded to the plates using the

flux-cored arc welding (FCAW) process with a nominal weld size of 6.4 mm (1/4 in.)"

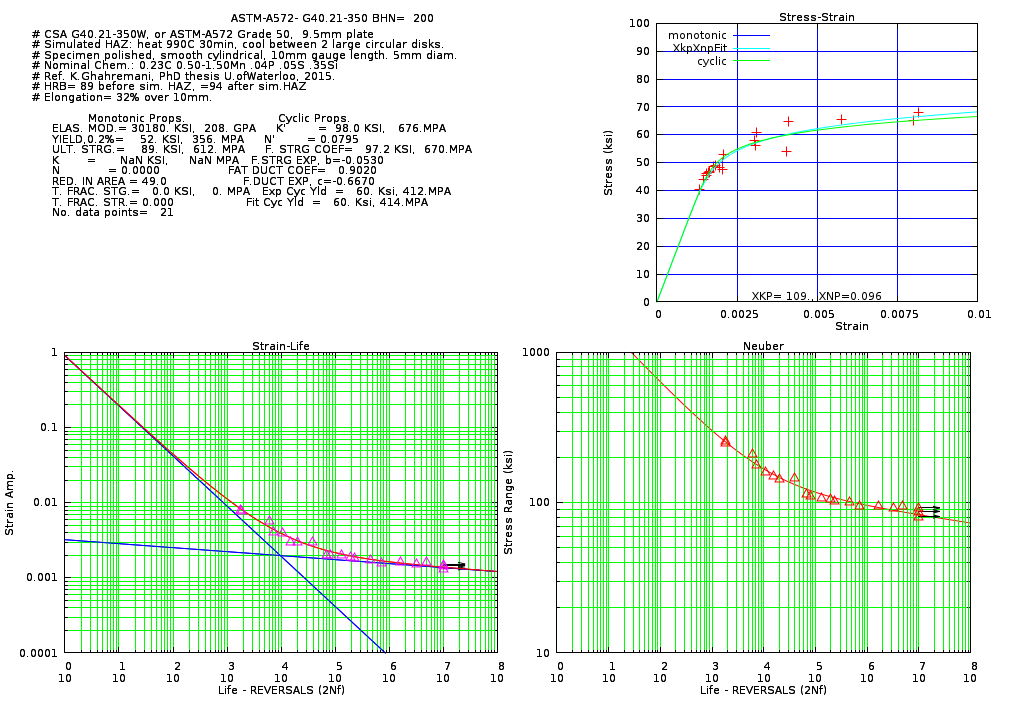

CSA G40.21 350W is a higher manganese structural steel. The "350" denotes

Nominal Chem. for CSA G40.21 350W:

(All elements are maximums allowed)

0.23C wt% 0.4Si 0.50-1.50Mn 0.04P 0.05_S

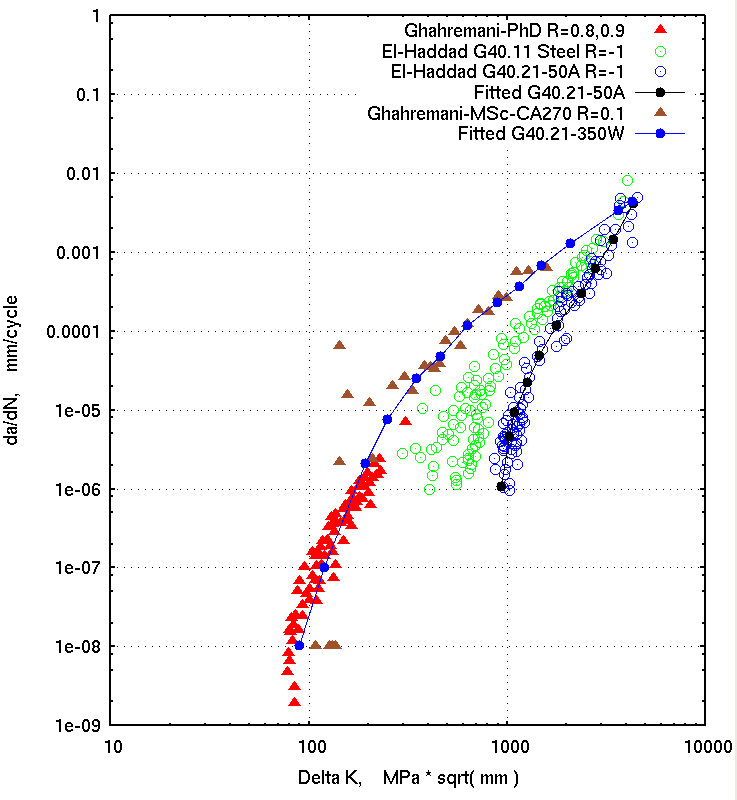

Crack Initiation and Propagation data for a simulated HAZ are available

here

Baseline crack initiation and propagation specimens were machined from

plates that were subjected to a simulated Heat Affected Zone (HAZ) operation:

1. Heat in furnace at 990 C for 30min

2. Cool between two contacting plates

3. Machine specimens (see PhD thesis for details)

The process increased the hardness from HRB=89 to HRB=94.

Table 1 Condition: As-Welded

Name Nf Smax mpa Smin mpa

---- --------- ----- -----

XCA-1 1995000 120 12

XCA-2 920000 160 16

LCA-1 27000 279 28

LCA-2 17000 342 34

Two variable amplitude VA1 and VA2 histories were tested on several samples. Note that these histories have the same name as used in Ghahremani's MSc thesis, but are different histories in the PhD. The PhD histories were supplied by Ghahremani to the FD+E Comm. and are shown graphically in figures 3 and 4.

Fig. 3: Variable amplitude history VA1; max=200, min=10.07

Fig. 4: Variable amplitude history VA2; max=200, min=3.94

Digital Versions of Test Histories:

Table 2 Condition: As-Welded, X section (transv. stiffener)

#Kasra Ghahremani PhD

Name Nf Smax mpa Smin mpa History

---- --------- ----- ----- ----

XAV1-1 3843000 180 10 VA1

XAV1-3 1131000 229 12 VA1

XAV1-3 713000 252 13 VA1

XAV1-4 397000 387 21 VA1

XAV2-1 8203000 167 7 VA2

XAV2-3 1921000 226 9 VA2

XAV2-3 1041000 319 13 VA2

XAV2-4 827000 387 16 VA2

Table 2 Condition: As-Welded, L section (double lap)

#Kasra Ghahremani PhD

Name Nf Smax mpa Smin mpa History

---- --------- ----- ----- ----

LAV1-1 652000 148 8 VA1

LAV1-2 1080000 159 8 VA1

LAV1-3 1651000 161 9 VA1

LAV1-4 468000 180 10 VA1

LAV1-5 56000 387 21 VA1

LAV2-1 9840000 136 6 VA2

LAV2-2 964000 179 7 VA2

LAV2-3 116000 387 16 VA2