(Click to enlarge)

(Click to enlarge)

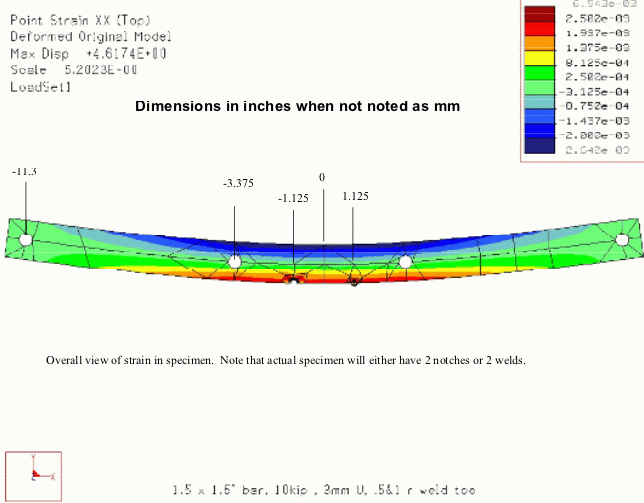

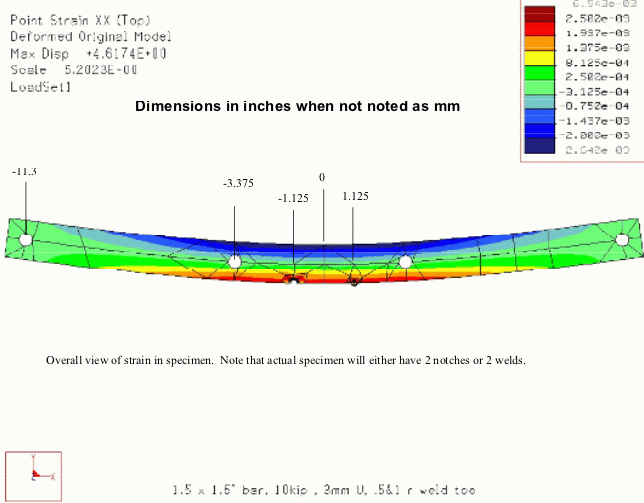

Fig. 1: Overview of square beam

The challenge is to predict the number of cycles at +/- 5,000 pounds

(initial load estimate, actual test load may vary) load to break the bar.

The specimens will be monitored to assess the portion of life before a

crack is identified and a measure of crack growth versus cycles.

Tom will have results for discussion at the Oct 15 2008 FDE meeting.

(Click to enlarge)

(Click to enlarge)

Fig. 1: Overview of square beam

Some of the specimen details are in figure 1. While the figure

shows one specimen with a weld and a notch, actual specimens have either

2 welds or 2 notches at the locations shown.

Material was normalized A36 (77- 78 HRB or 137-140 BHN)

The welds were made with a Lincoln Powerwave 455, STT Mode 22,

with 90/10 gas mixture using L50 0.045" diameter wire.

Welder settings were 80/380/10

A large amount of further information can be found in a

lowcarbon.html

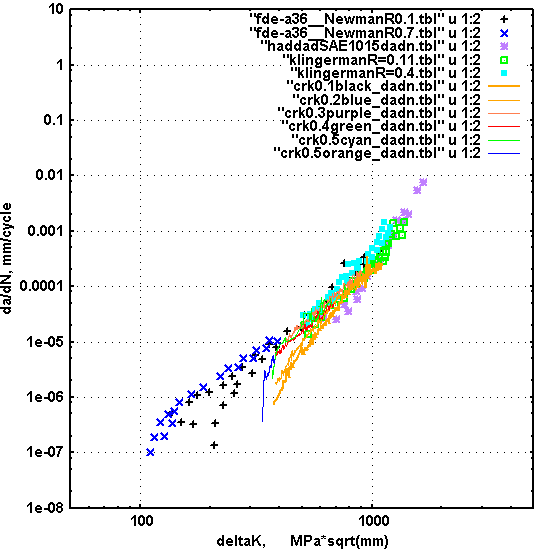

Crack propagation da/dN vs ΔK data was collected from presentations

Fig. 2 : Collected A36 and similar low carbon steel da/dN vs ΔK data.

In each test specimen the two notches are either both grooves or both weld beads.

See figure 1 for other geometric details. Also see

Presentation by T. Cordes (pdf 16Mb)

for pictures.

1 6000 Lbs (26.689 kN),

2 5000 Lbs (22.241 kN)

3 3500 Lbs (15.569 kN)

Notched Specimen Test Results Summary

at +/- 5000 Lbs

Fatigue Life Fatigue Life

To First To Failure

Detectable To Carry

Testing Performed By Crack (Cycles) Load (Cycles)

----------------------------------------- ------- ---------

Original FD+E Round Robin Test Result 5,000 21,975

Mississippi State University (MSU) Group 6 5,000 26,365

Mississippi State University (MSU) Group 5 5,504 24,443

Mississippi State University (MSU) Group 4 6,000 27,216

Mississippi State University (MSU) Group 3 7,200 24,985

Mississippi State University (MSU) Group 2 12,224 24,271

Mississippi State University (MSU) Group 1 14,097 24,034

Other Welded and Notched Specimen

Test Results Summary.

Load First Crack Crack all the Obvious Edge Failure

Specimen R=-1.0 Indication(s) way across Crack Two Pieces

Configuration Lbs Cycles Cycles Cycles Cycles

---------- ------ ----------- ------------ ----------- ----------

Weld 6,000 18,000 20,700 23,400 30,964

Weld 5,000 55,300 94,000 168,000 198,282

Notch 5,000 5,000 8,000 14,000 21,975

Notch 3,500 62,000 106,000 115,000 154,494