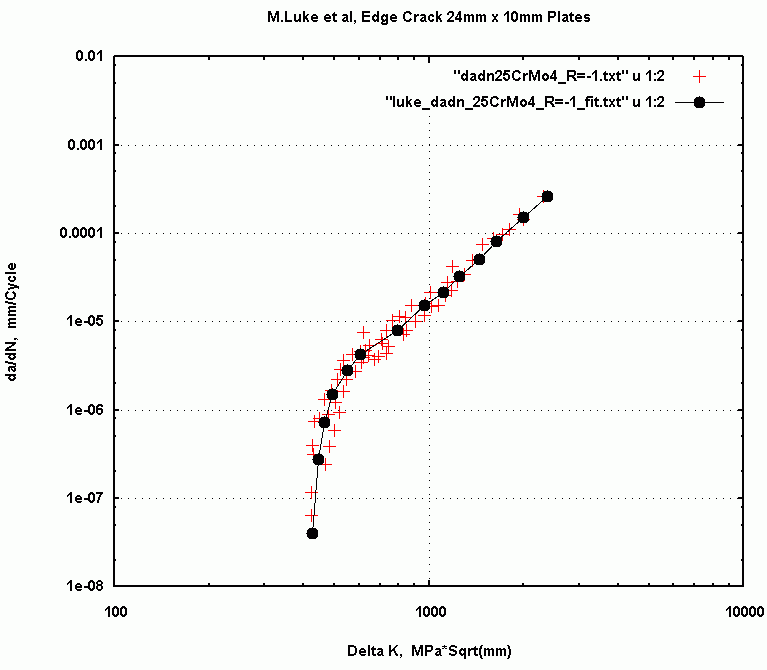

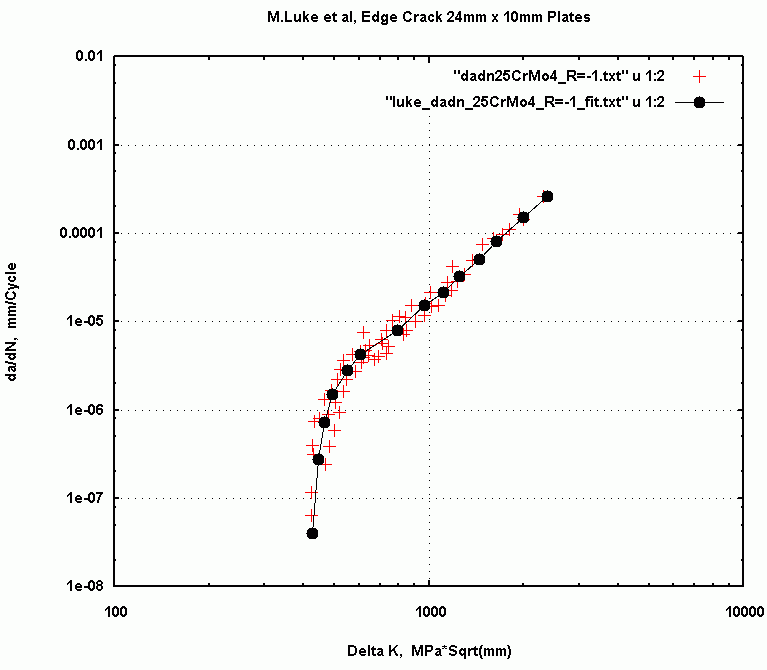

Fig. 1: Fitted da/dN points of 25CrMo4 Steel.

25CrMo4 axle steel Yield= 550 mpa

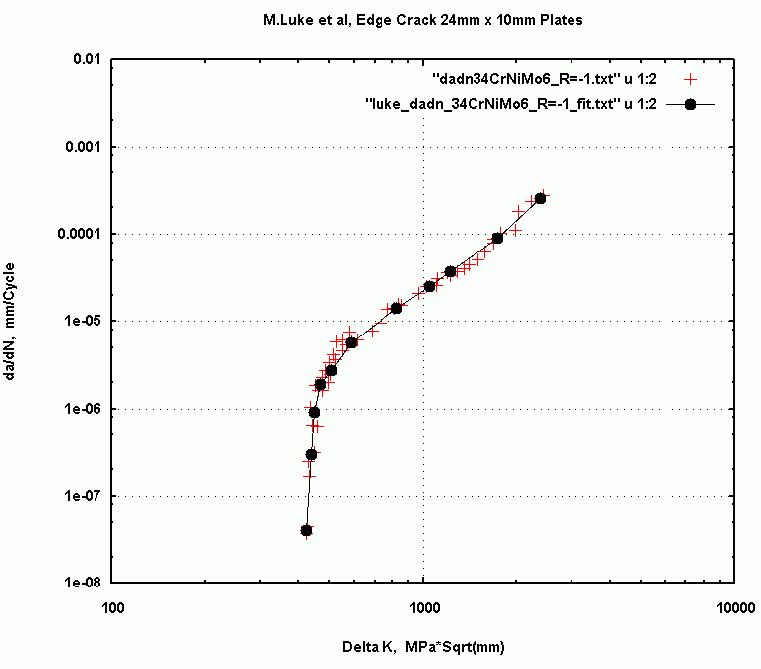

34CrNiMo6 high strength steel = 950 mpa

Plate specimens (width 24mm, thickness 10mm) used for generating baseline da/dN

Curves for da/dN baseline data were generated with tests using load ratios of

R=-1.0 and R=0.1 for both materials. R=-1.0 da/dN data from the reference

was fitted visually to the as shown if figure 1 and 2. (black points)

Fig. 1: Fitted da/dN points of 25CrMo4 Steel.

Fig. 2: Fitted da/dN points of 34CrNiMo6 Steel.

The original paper by Luke et al did not report any initiation tests.

The sub-blocks are divided into sub-block segments and the arrangement of

the segments is described in the text file

testLoads.txt

A program was used to convert the segment descriptors into a half cycle by

half cycle sequence. The program is available here:

A peak by peak history of membrane (Pm) and bending (Pb=0.0) are available

in the file

c100histPm.txt (1 Mb)

In the history the "100" value for the peak is proportional to the test reference stress

for sub-block 1 (the lowest stress sub-block). The arrangement of the sub-blocks and

their maxima stresses is a bit complicated and the reader is referred to the

paper by Luke et al for a full explanation.

34CrNiMo6 Steel: Nf af

Delta S= 200 mpa : Fracture at 277000 7.7 mm

Delta S= 200 mpa : Fracture at 298000 8.4 mm

Delta S= 120 mpa : Fracture at 1380000 8.3 mm

25CrMo4 Steel:

Delta S= 200 mpa : Fracture at 156000 6.7 mm

Delta S= 200 mpa : Fracture at 159000 6.4 mm

Delta S= 120 mpa : Fracture at 1450000 10.0 mm

(See Luke et al. for experimental crack length vs. cycles data plots )