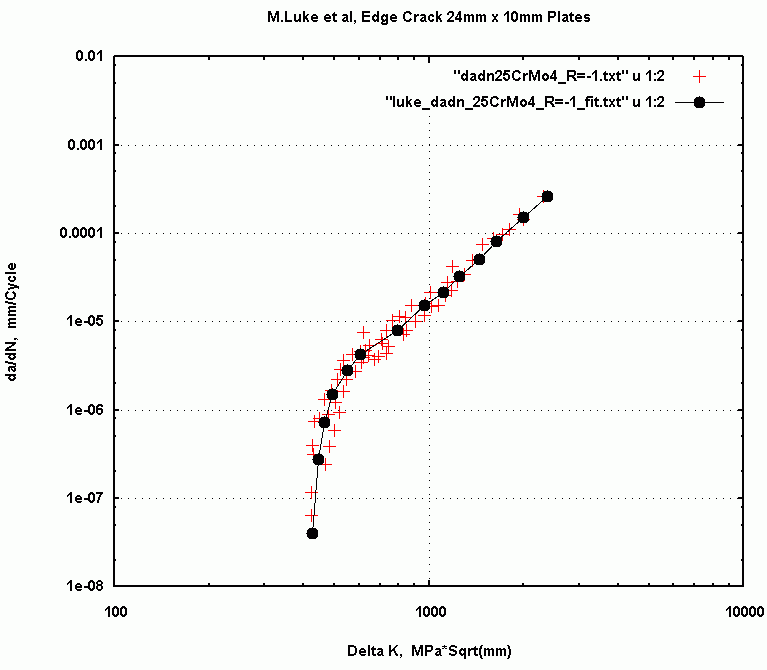

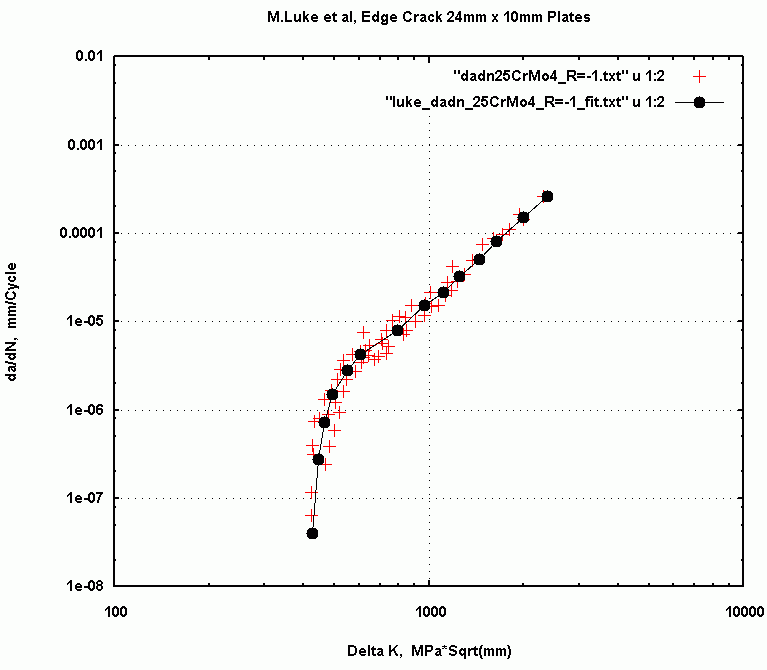

Fig. 1: Fitted da/dN points of 25CrMo4 Steel.

Fig. 1: Fitted da/dN points of 25CrMo4 Steel.

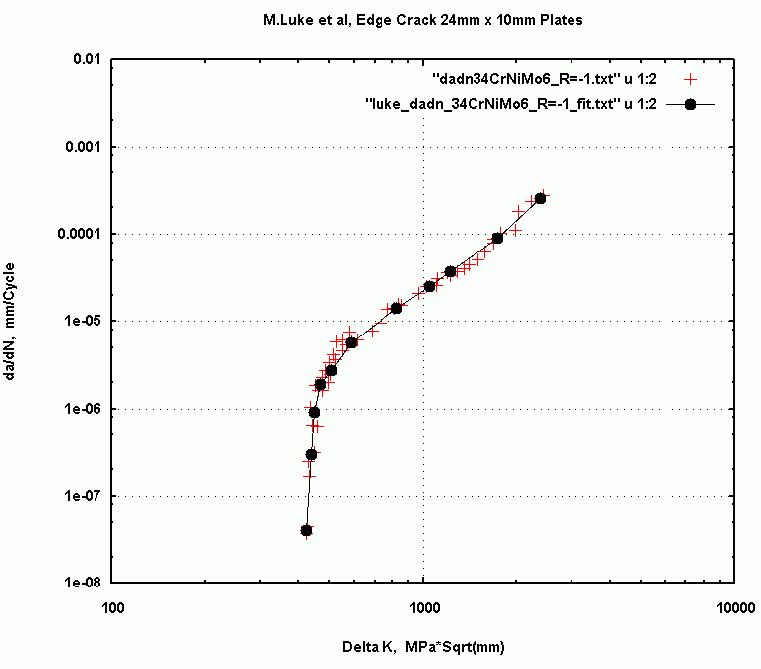

Fig. 2: Fitted da/dN points of 34CrNiMo6 Steel.

For the crack initiation part of the simulation four data sets were merged into

one file

(Raw available here).

and the "fitted" stress-strain-life curve

(Fitted file available here)

was then used to predict crack initiation life for an uncracked sample subjected

to the same nominal stress history. The original paper by Luke et al did not

report any initiation tests, but the simulations are presented below to serve as

a comparison alongside the crack propagation predictions.

The sub-blocks are divided into sub-block segments and the arrangement of

the segments is described in the text file

here.

A program was used to convert the segment descriptors into a half cycle by

half cycle sequence. The program is available here:

A peak by peak history of membrane (Pm) and bending (Pb=0.0) are available

in the file

c100histPm.txt (1 Mb)

In the history the "100" value for the peak is proportional to the test reference stress

for sub-block 1 (the lowest stress sub-block). The arrangement of the sub-blocks and

their maxima stresses is a bit complicated and the reader is referred to the

paper by Luke et al for a full explanation.

Other run-time files are:

34CrNiMo6 Steel: Delta S= 200 mpa : Fracture at 77688 cycles @ a= 3.97 mm 0.027 sec cpu Delta S= 120 mpa : Fracture at 701701 cycles @ a= 6.70 mm 0.126 sec cpu 25CrMo4 Steel: Delta S= 200 mpa : Fracture at 77688 cycles @ a= 3.72 mm 0.021 sec cpu Delta S= 120 mpa : Fracture at 987701 cycles @ a= 6.49 mm 0.152 sec cpu (See Luke et al for experimental crack length vs. cycles data)The higher stress level simulations are within a factor of two of experimental lives, while

Damage computation was made for each half cycle. Both materials simulated

at Delta S= 200 mpa failed at the first large +-280 mpa cycle in the 4th

history repetition.

It should be noted that the simulation program corrects for material memory

but it does not presently compensate for overloads. The mean stress correction

and the crack closure code segments have been turned off, resulting in a simulation

that follows BS7910-2005. For this particular load history material memory compensation

is not expected to alter the results greatly.

The simulation program generates a report for each test and the pdf files are

available here: